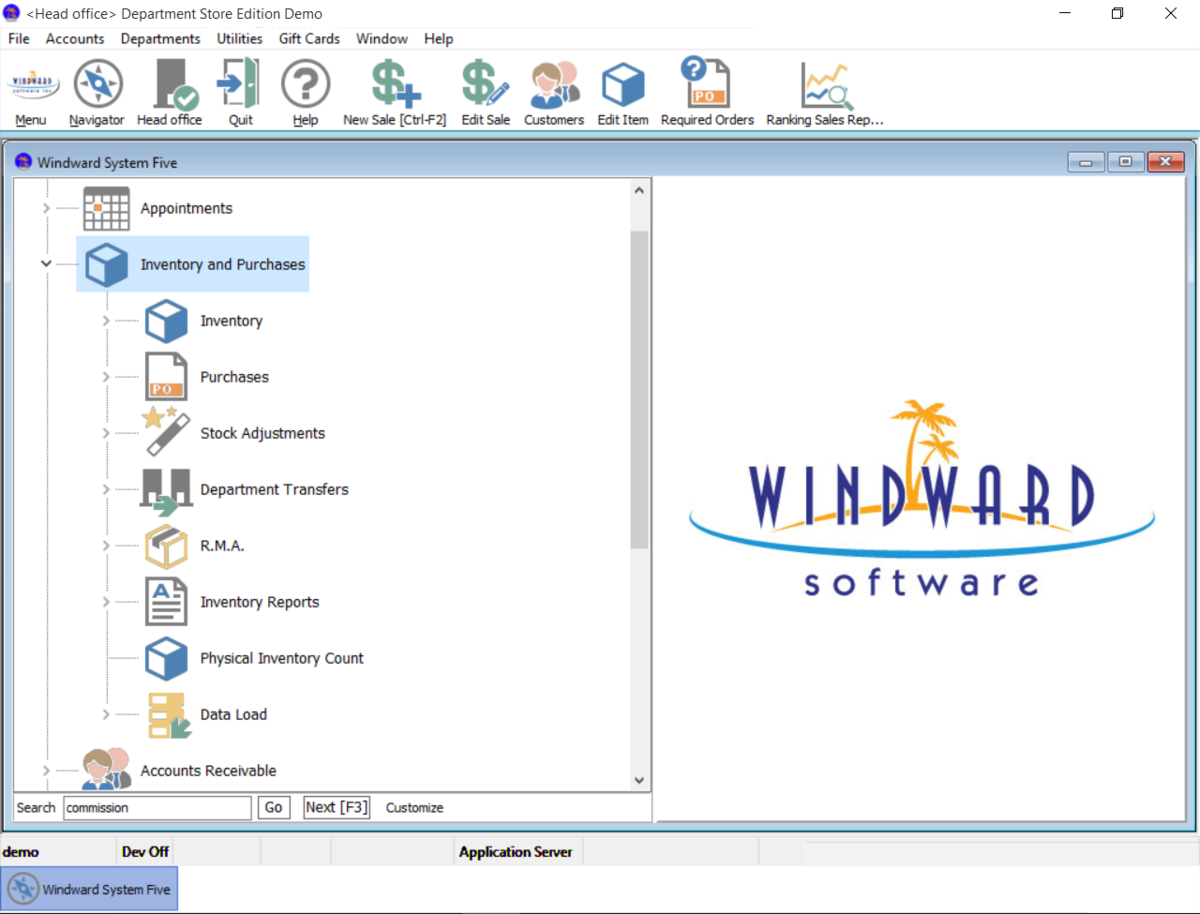

Improve Cost Control Processes

Businesses today often make or break it based on how effectively they manage their inventory. Windward Software gives you real-time inventory management through integration of all aspects of your business:

- Point of sale

- Accounting

- Inventory control

This combined approach quickly pays for itself through reduced inventory shrinkage, cash flow optimization and improved customer satisfaction by minimizing lost sales from running out of stock. Windward System Five's inventory software makes it easy keep a watchful eye over your stock levels.

- Reduce inventory shrinkage

- Optimize your cash flow

- Improve customer satisfaction

- Reduce out-of-stock items

- Use barcodes tighten inventory control

- Add security with serial number tracking

- Easily calculate taxes for any jurisdiction

- Use multiple fields to search inventory

Just-in-time Inventory

Windward’s inventory software maximizes your benefits from just-in-time inventory, providing a complete inventory management solution for your business:

- Controlling inventory

- Searching and tracking items

- Ensuring adequate supplies

- Increasing warehouse productivity

- Reducing paper flow

Windward Software has the ability to input and track manufacturers’ serial numbers, generate and print internal barcodes, as well as track true cost and warranty. This is what sets us apart from other inventory management systems.

Inventory Reporting

Once you begin to generate some history, our inventory software will examine your sales and recommend new highs and lows based on the sales volumes, shipping times and sales trends. With barcode support, you can ensure accurate control, counting and selling of your inventory. While barcode support is included with Windward Software, barcodes are not for everyone, and we can show you several alternate methods of controlling inventory.

If you have a large warehouse, or you just need a more advanced control system for finding your inventory items, you should check out our Advanced Inventory Control (AIC).

Consignment Inventory

Our consignment feature is used to keep track of inventory that you don't own, but at the time of sale, you must pay for it. You'll be able to generate several reports, including a list of unsold consignment inventory, as well as a list of inventory sold on consignment, but not yet paid for.

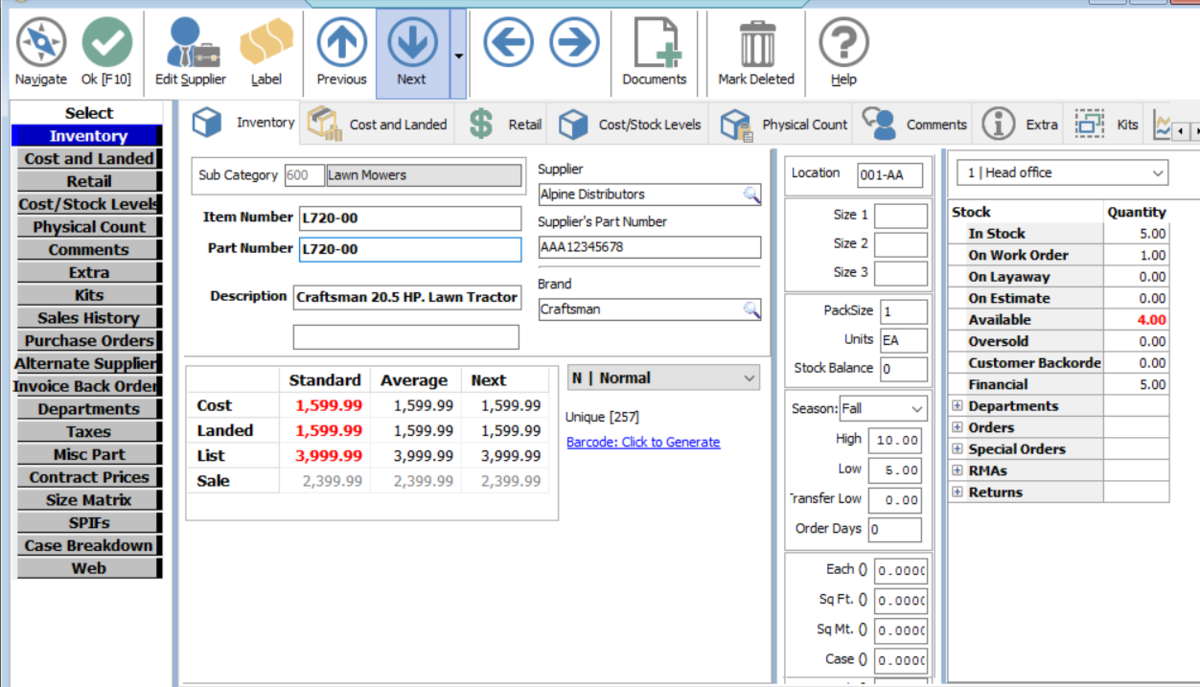

Find Inventory

Having the ability to find inventory quickly and easily is essential to running an efficient business. The most practical way to find an inventory item is by the part number, and it’s something most inventory software programs on the market can do. However, Windward System Five also lets you search by other methods such as:

- Supplier’s part number

- Product description (including partial descriptions)

- Supplier name

- Main and sub category

- Other options

Using Search Fields

If you're looking for things by size—such as clothing, shoes or tires—you can use the size fields to perform a search. One of the most powerful search methods is to enter several different fields and only find those records that match all of the criteria.

If you’re struggling to find an item, you can cast a wider net by starting your search in a main category field. Once you narrow it down to a sub category, you can finally search for specific parts. This is beneficial when you’re searching for an out-of-stock item to reorder because you might not have the part or barcode number handy.

Windward Software can also manage your special inventory items.

Search Methods

Windward Software allows you to easily see:

- Quantities in stock

- Committed-to work orders

- Layaways

- Quantities available to sell

System Five is also extremely powerful when it comes to inventory control, pricing and maintenance. It will support regular part numbers, alphanumeric part numbers and barcode numbers. It will even keep track of the supplier's part number, as that will often be different than the one you use on a day-to-day basis.

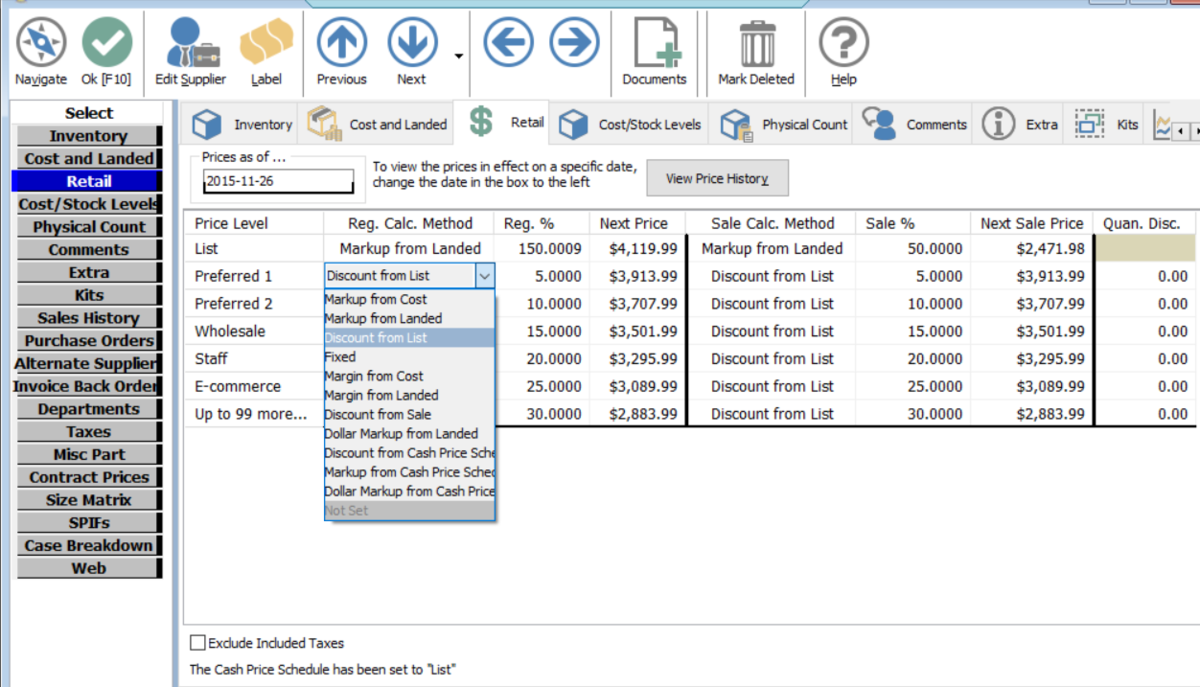

Cost and Selling Prices

Inventory is typically costed on a first-in, first-out basis, but the pricing can be based on your standard price, next price, average price, or you can fix the price and lock it in. You can choose to work with one main list price, or add up to 99 different price schedules for different types of customers.

When you cost using the first-in, first-out method, inventory reports show a weighted average of the remaining stock (costing by average method is available by request). You can also list price and 99 price levels of different prices for different customers.

You might not need all of these powerful features to start with, but it’s a good example of how Windward’s inventory software provides you with room to grow.

Expected Price vs Actual Price

There are several things to consider when looking at inventory costs. The first is differentiating between the price you expect to pay for an item, versus what you actually paid for the item. These two might sound similar, but they’re quite different. In simple inventory software systems, you would enter one cost price and that's it. If only it were so easy.

With Windward System Five, the price you expect to pay is stored with the main inventory record. In addition to the raw inventory cost, you can also add freight, duty and other charges such as insurance. These numbers are added together to give you your landed cost at your doorstep. When pricing goods for resale, it's important to know the landed cost, including all of the hidden charges, so you don’t undercut youself.

Multiple Suppliers

If you have the option of buying the same item from competing suppliers, our inventory software lets you enter alternate supplier information, including the cost from each. Before you purchase from a different supplier, you'll be able to view their cost from the last time you purchased from them.

On your actual costs, once you land the inventory at your doorstep and add the items into inventory, the inventory software will create a record showing the actual cost in dollars, instead of the foreign currency. This is the cost that will be used when costing invoices as they are entered into the system. The inventory is removed on a first-in, first-out basis, which is usually the most accurate method.

When you print an inventory report, you'll be able to view your actual cost based on a weighted average of what is actually left in stock. So, even though the system is costing on a first-in, first-out basis, the inventory remaining on hand is properly calculated for report and inventory valuation purposes.

The exception to first-in, first-out costing is when dealing with serial numbers. Each serial number is stored with it's own unique cost and that is what's used on the invoices.

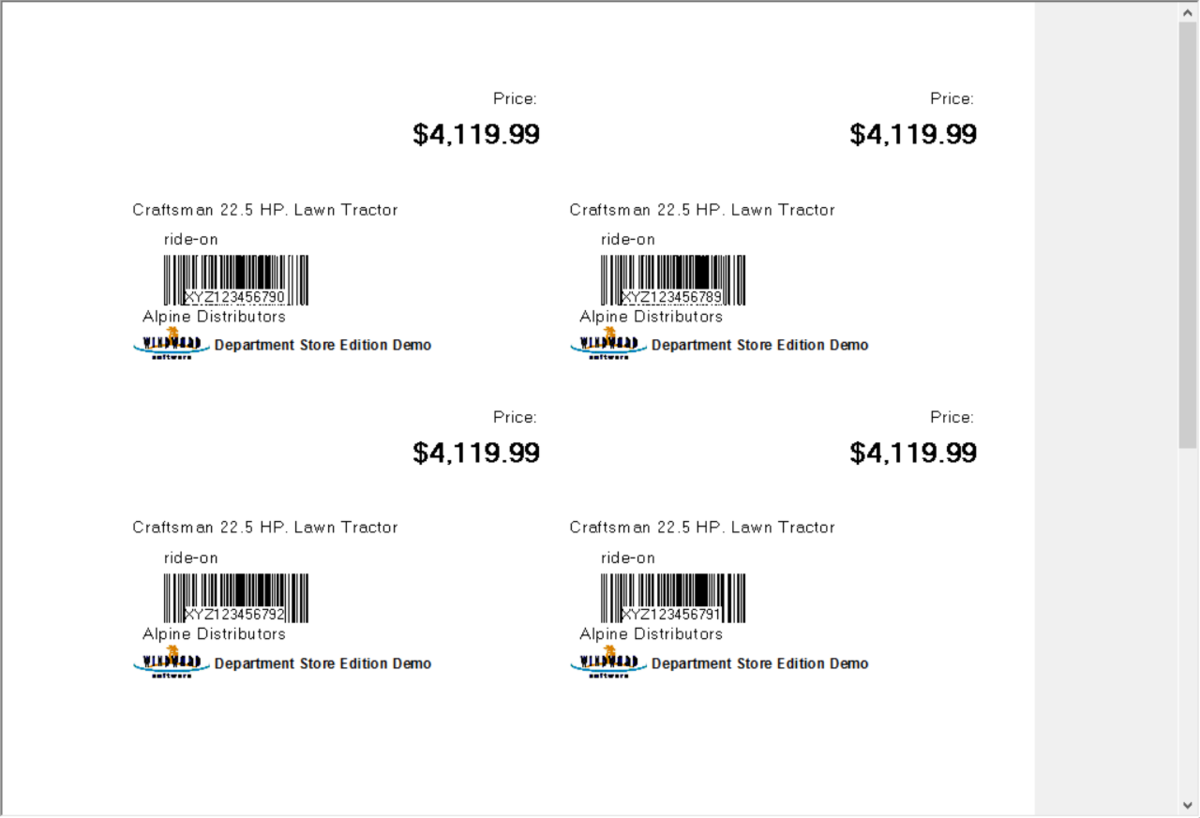

Barcode Support

Windward Software’s inventory management supports barcodes at point-of-sale, receiving and when counting stock levels. You can even print your own barcodes. If your items come barcoded from a supplier, you can enter the barcode number into the item number field.

UPC Barcode numbers are either 10 or 12 characters in length, depending on whether your scanners are set up to accept or reject the small numbers before and after the main barcode number. Windward System Five’s inventory software is versatile enough to handle both lengths, as well as other barcodes up to 20 characters.

Save Time: One of the main benefits of barcode scanners is at the checkout counter, where they speed throughput, thereby improving the customer experience. However, they also save significant time in other applications such as taking inventory.

For example, one of our customer’s six-month inventory task used to take a full crew of 25 employees about two days to complete. It resulted in lost productivity and increased overtime expense. Using our inventory software and some barcode scanners, the customer completed the same task in about five hours using only four employees. As an added bonus, they are now able to take inventory more frequently, thereby improving the accuracy of their stock counts.

Similarly, time savings can be realized when receiving purchase orders. Day after day, the small, incremental savings from scanning scan barcodes, as opposed to writing down part and serial numbers, can add up to substantial gains in productivity.

Reduce Errors: Data entry errors at point of sale and receiving can lead to unnecessary expenses, and other problems such as:

- Dissatisfied customers

- Extra freight costs

- Lost productivity

- Employee frustration

The use of barcodes effectively eliminates data entry errors. Scanners are incredibly accurate, with error rates as low as one error per 36 trillion characters, depending on the type of barcode used. By contrast, the typical error rate for human data entry is about one error per 300 characters. This fact alone makes inventory software a valuable tool in terms of accuracy and saving time.

Reduce Regulatory Requirements Hassles: Regulatory agencies such as the FDA, USDA and EPA sometimes impose labeling requirements that businesses must meet. You can keep this added expense to minimum, and save time, by using barcodes in your operations. You can collect required shipping manifest information quickly and accurately by scanning the barcode labels that you printed to satisfy the regulatory agency.

Multiple Barcodes

Windward’s inventory software also gives you the option of attaching multiple barcode numbers to a single item, and search for it using any one of them. Of course, you might wonder why you'd want more than one barcode per item. We wonder that too, but manufacturers sometimes change the barcode for the same item. We have no control over that, but we’ve made sure our inventory management system can handle whatever they throw our way.

Serial Number Tracking

You can flag some of the items in the system for use with serial numbers. When you do this, you must enter the serial numbers of the items using the inventory software as you receive the stock, as well as when you sell the items. Once entered, the system will tell you for each serialized item:

- When you purchased it

- Who you got it from

- Purchase order number it came in on

- Who you sold it to

- Invoice number

- Date of sale

- How much you paid for it

- How much you sold it for

This kind of history is invaluable if you ever have to return the item on warranty.

Note that our inventory software lets you sell an item on the invoice without the serial number, allowing you to go back and add it once the item has been picked from the warehouse and delivered to the customer. That way you won’t have to crawl over boxes trying to match a specific serial number to an invoice.

Part Numbers

Part numbers are also commonly referred to as:

- Barcode numbers

- SKU's

- Item numbers

- Model numbers

It's the identifier on the package that ensures you’re selling the correct item at point of sale. It should be a simple concept, but unfortunately many manufactures and wholesalers have made it complex and we simply have to work with it.

The part number you use in the store may be different than the one you use when ordering from the manufacturer. Similarly, wholesalers may use their own numbering system, separate from the manufacturer or what’s printed on the outside of the box. And finally, the barcode number may be different again.

Fortunately, Windward’s inventory software handles all of this by allowing different part numbers for each item. As a result, you can find the item by any barcode number, part number, supplier part number etc.

In an ideal world, each item should have just one barcode number so that when you scan it, you get the right item. However, to save costs in packaging, some manufacturers use the same barcode number for multiple items. For example, in a scrapbooking company, different colors of paper or stickers may all have the same barcode number and sell for the same price. This is problematic because in order to keep track of which colors you have in stock, or determine which is most popular, you need to select the correct item.

Windward System Five inventory control software allows for one barcode to point to different inventory items. And the reverse is also true. One inventory item may have been superseded or upgraded over the years and have a new barcode number. It's possible to have many different barcode numbers referencing the same single item in your database.

We don't make the rules, but our inventory software is flexible enough to work with the weird rules of others.

Kits (Bill of Materials)

Kits, which are also known as a bill of materials, are a collection of items that can be sold at one time by selling just one part number instead of having to enter the individual part number of each item being sold. They can be used for small-scale manufacturing businesses to selling groupings of inventory.

Many of our competitors support kits to some degree, but Windward System Five inventory software will accommodate the most elaborate kits you can think of.

Dynamic kits: Dynamic kits remove the inventory (raw materials) from stock as the kit is sold. By definition, there are never any kits in stock, only raw materials, and when the kit is sold, each of the items within the kit is removed from stock.

Static kits: Static kits are built before the customer arrives. When you create a static kit, the system will remove the raw materials from stock and then add the kit into stock so that it’s available to sell. This is useful for a small manufacturing operation that wants to record how many items have been built and are ready for sale, while providing a quick summary of the raw materials that are left over. Our inventory software can analyze the remaining inventory and let you know how many kits you can build from the raw materials. It will also let you know which materials you need to purchase in order to build a certain number of kits.

Tag-along kits: Tag-along kits are a variation on dynamic kits where, as the raw materials are sold, a kit is also sold. If an item is sold with another item unconditionally, you can use our inventory software to build a tag-along kit instead of having to build the item and insert it within a kit every time you make a sale. A good example of this is a business that sells bottles of pop that are always sold with a deposit.

Exploding kits: As the name indicates, exploding a kit onto an invoice places all the individual items so each one can be individually priced. It also allows you to substitute one item for another. This is an especially handy feature for businesses that sell computer systems. A customer may order a standard computer, but then decide upgrade the hard drive. If you explode the kit onto the invoice, it will normally be priced at zero and each item will instead be priced.

Priced as a Kit or as Sum of the Parts: Sometimes you’ll want to give price incentives if a customer purchases the entire kit. Other times, you’ll decide to charge more because you're adding value by assembling all the parts in one convenient package. Or you may want to simply add up the cost of the items and sell them at the regular price. With Windward’s inventory software, the choice is yours.

Taxes

Standard sales tax: If you have just one simple sales tax, our inventory software will handle it with ease. For each customer, you can set a flag marking them as taxable or tax-exempt, and you can override that setting on the invoice if required.

Tax zones for different states or counties: In some areas, such as California, each county has a different sales tax that is comprised of the state portion and the county portion. If you’re delivering items to these different counties, you must charge the correct tax for each one and remit that at month end. With Windward System Five, you can create a series of tax tables and either place the customer, the invoice, or both, within a given table. Each table can post to a separate ledger number for sales tax collected so that it can be easily remitted.

Environmental taxes: Governments love to tax, and society as a whole is concerned about the environment. Many states are now cashing in by taxing extra on the sale of things like tires, batteries, oil changes and paint. The list of taxable items will only expand as governments ramp up this practice.

With Windward System Five’s inventory software, you can easily track these taxes and automatically charge them when selling inventory. These levies are generally assigned a fixed amount (such as $3 per tire or $5 per battery), but in some cases the charges will vary. For instance, a larger paint container is charged at a higher rate than a smaller one.

Just keep things interesting, there is often sales tax on the environment tax, but not always. This is can be set with a soft switch in our inventory control program.

Inventory Comments

Need to add a comment to your inventory item? Which kind and for what reason? With Windward’s inventory software, you’ve got options.

Printable invoice comments: This kind of comment will be dragged onto the invoice and then printed on the customer's copy at point of sale. You have the option of editing or changing the comment on the invoice before printing it if you need to. This feature is useful for selling service jobs where you ‘can’ the comment and use it repeatedly (for example, rotating and balancing the tires).

It can also be used for warnings if selling hazardous goods by automatically printing the warnings and/or special instructions on the invoice. In some territories, businesses are required by law to inform the customer about the hazardous goods, and our inventory software can create specific warning on invoices to fulfill that obligation. Without it, you could be liable for damages. Printable invoice comments can be up to seven lines long and 60 characters wide.

Printable purchase order comments: The comment you give your supplier will probably be different than the one printed on your customer’s invoice, so we've given you the option for both. Purchase order comments will be printed on the purchase order, right under the part number, description and quantity, and can contain special instructions such as shipping method, color and handling instructions.

Inventory selling warning comments: The warning comment is NOT printed on the invoice, but when the clerk selects that part, it will display the warning comment in a big red box on the screen. It can be used for a warning about problems with the item, or to ask the customer certain questions to ensure they get what they need. For example, if a customer is buying a computer game, the system may warn the clerk that the package selected is only compatible with an Apple computer and not a PC.

It can also be used for upselling the customer. If a customer is buying a printer, the inventory software can generate a warning comment prompting the clerk to ask if they need paper or ink to go with it. While warning comments are generally not printed on the invoice, this function can be activated by setting a soft switch in the master file. Also if you’re dealing with a piece of art and need up to 200 lines to describe it, instead of the standard seven lines, Windward can do it.

Purchase order warning comments: A purchase order warning comment will, as the name implies, bring up a big red box when a specific part is selected on a purchase order. It can be used to remind the user of past problems with the item, or to ensure additional products are ordered at the same time. A typical warning would be ‘batteries not included.’

Freeform Comments: